Roll Tooling Design

Roll Tooling Design

The most important step was the design of the rolls for the roll forming process.

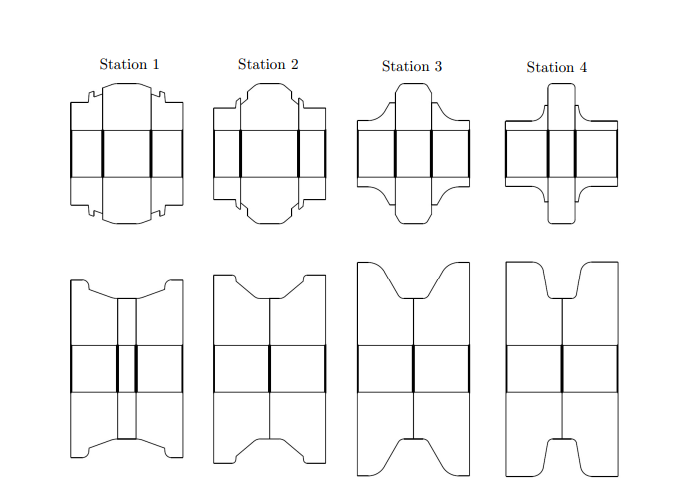

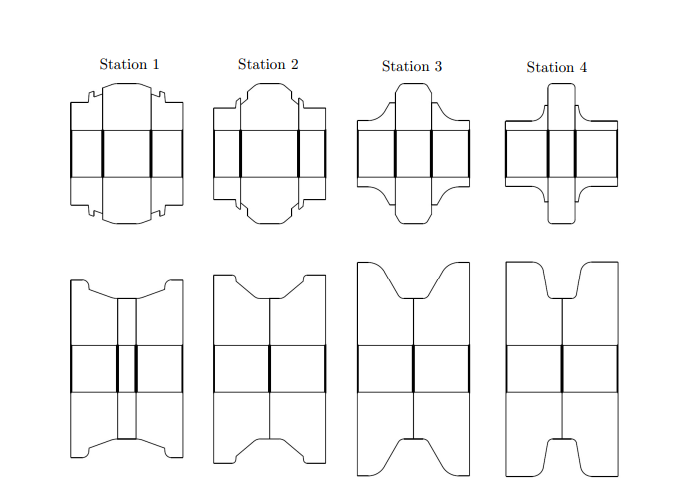

Tool design is done in COPRA® RF using the flower diagram as a base. Each step is displayed individually, and the rolls are created automatically from the profile outline.

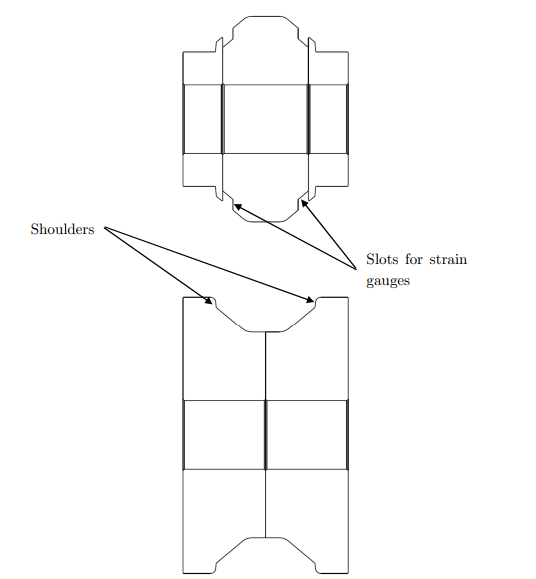

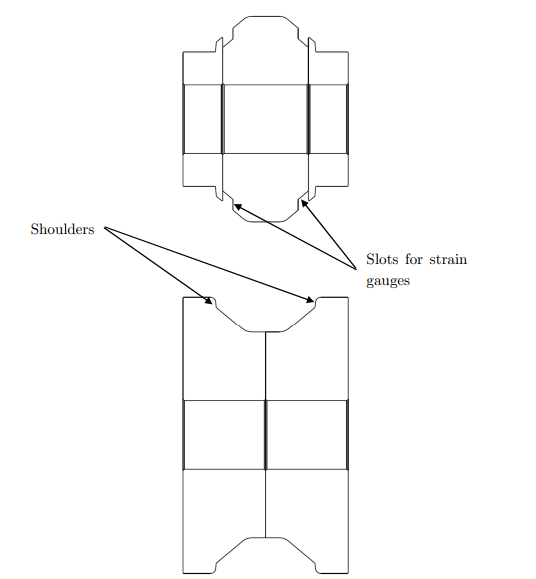

A shoulder was designed on the rolls (Figure 1), on each side of the profile.

Figure 1

This had the purpose of guiding the sheet inside the rolls, keeping it aligned. These shoulders were rounded on each roll set in order to guide the sheet into the rolls. When the sheet first enters the roll, it still has the shape of the previous pass. The rounded shoulders guide the strip edge into the rolls for the next pass.

Figure 1

This had the purpose of guiding the sheet inside the rolls, keeping it aligned. These shoulders were rounded on each roll set in order to guide the sheet into the rolls. When the sheet first enters the roll, it still has the shape of the previous pass. The rounded shoulders guide the strip edge into the rolls for the next pass.

The rolls used in the present work were also designed with a slot on either side (Figure 2). This was done in order to enable the placement of the strain gauges on the sheet during forming, to evaluate the longitudinal strain applied on the sheet in each forming step. This investigation was not done in the present work but the possibility was left open for future investigations using the same equipment.

The final roll design is shown in Figure 2.

Figure 2

Figure 2